FAN / BLOWER DESIGN & SELECTION |

|

Industrial Air Flow Design Principles for Fan / Blower Applications. |

As each industrial air moving system has it's own particular design and system effects, it would be impossible to predict the infinite amount of all possible system effects or phenomenon that may occur in a particular application. This information will center on heavy duty industrial process air moving applications. For Air Conditioning design principals, light duty commercial (Schools - Restaurants Etc.) please search the web for keywords, "commercial air moving" or look in the consumer yellow pages under "air conditioning". |

| Process air moving applications |

| • |

Humidifiers and Dehumidifiers |

• |

Boilers |

| • |

Pneumatic conveying |

• |

Scrubbers |

| • |

Paint and coating lines |

• |

Heaters |

| • |

Incineration. |

• |

Dryers |

| • |

Gas extraction |

• |

Dust Collection |

| • |

Chillers |

• |

Solvent recovery |

| • |

Combustion |

• |

Air filtration |

| • |

Ovens / Curing systems |

• |

Air Supply and Exhaust |

|

| |

|

|

| Industrial Fan / Blower Types - three main categories |

| Centrifugal |

Backwardly inclined -Airfoil, Single thickness, Backward curved. |

| Forward curved - general light duty multiplied slow speed. |

| Radial blade type - Open, Backplated, Rimmed, Reinforced, for rugged applications. |

| Inline centrifugal - using Airfoil or Single thickness backwardly inclined wheel. |

| High Pressure. - Narrow width open and radial tipped design. |

| Radial Tipped - High rim or tip speed capability, resulting in high flow and pressure.. |

| |

|

| Axial |

Propeller. |

| Vaneaxial. |

| Tubeaxial. |

| Ductaxial. |

| Inline Centrifugal. |

| Ring / panel Venturi. |

| |

|

| Plug and Plenum Fans |

Unhoused impeller using one of the centrifugal impellers listed above. |

| |

|

| Others |

Many other sub categories, however most are all based on above main impeller types |

|

| |

|

|

| Fan / Blower Performance |

As a fan wheel or impeller rotates, the Impeller through centrifugal force creates vacuum or low pressure at its inlet suction side. In turn, the impeller creates a positive pressure, inducing a force of air on the discharge side. These basic principals are similar to a pump or water wheel, in which the air is conveyed from the suction to discharge. |

| |

|

|

| The affinity laws or centrifugal laws apply to fans similarly as in centrifugal pumps. |

Flow varies in direct proportion to change in RPM.

CFM (new) = [RPM(new) / RPM(old)] x CFM(old)

SP varies in proportion to change in RPM

SP(new) = [RPM(new) / RPM(old)] x SP(old)

Fan brake horsepower varies proportionally as the cube of the change in RPM.

BHP(new) = [RPM(new) / RPM(old)] x BHP(old) |

Request Quote |

| |

These factors only apply with changes to speed.

Should the system be altered in anyway through addition of "resistance" devices, such as dampers or changes in existing system design, a new system design must be calculated. |

| |

|

| |

| |

|

| |

| |

| |

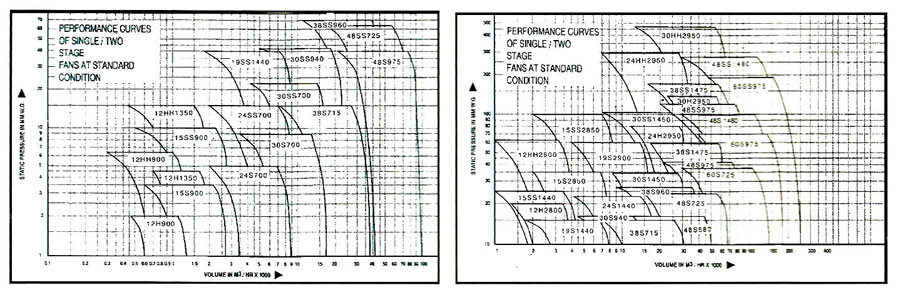

| QUICK SELECTION CHART FOR YOUR REQUIREMENT |

|

| |

|

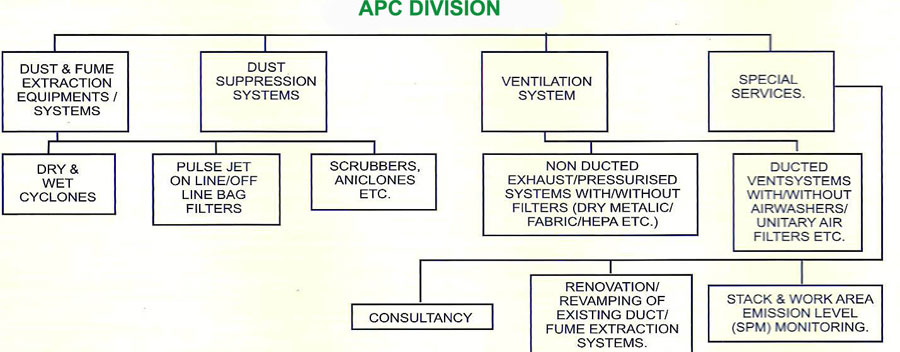

| AIR POLLUTION CONTROL DIVISIONN |

| PROJECT |

|

| EQUIPMENT - SELECTION |

OUR APC DIVISION IS BACKED BY THE PIONEERS AND THUS OFFERS YOU THE MOST COST AND ENERGY EFFICIENT. TAILOR MADE EQUIPMENT SYSTEMS ARE GUARANTEED TO PERFORM AND SATISFY THE MOST STRINGENT TESTE SET BY THE GOVT. OF INDIA (CPCB) AS WEL AS BY THE INTERNATIONAL AUTHORITIES. |

| SYSTEM DESIGN |

| SUPPLY - INSTALLATION |

| COMMISSIONING |

| EMISSION LEVEL TESTS |

|

| |

| Abbreviation : |

S-Std. Impeller Single Stage : SS-Std. Impeller Two Stages

H-High Pressure Impeller Single Stage : HH-High pressure Impeller Two Stage.

GS-Guide Vane at Upstream with Std. Impeller : HG-Guide Vane at down Stream with High Pressure Impeller. |

| Calculation of Fan Power |

| |

| Fan Power In K.W. : = Air Capacity in M /Hr x Total Pressure In mm SWG x 0.746 |

| 2745 x Total Fan Efficiency in % |

| |

Total Pressure = Static Pressure + Velocity Pressure Qutlet

Total Efficiency From Fan Selection Chart. |

| |

| SPECIAL SERVICES : |

CONSULTANCY - SYSTEM DESIGN - TROUBLE SHOOTING - FIELD BALANCING

FIELD TESTING - PERIODICAL SERVICING OF EQUIPMENT ETC. |

| |

| To Obtain the best Equipment and to the most prompt and Efficient after Sales Services please Contact |

| |

|

| To increase your System Efficiency use only RRIPL Axial Flow & Centrifugal Fans. |

| |

| |

|

|